The air supply to the 3408 Engine flows through a “bonnet-type” inlet screen (1), which is mounted on the hood. A daily inspection of the inlet screen is important to ensure that dirt or other material does not clog the screen and restrict the flow of air to the engine. Also, a tubular-type precleaner is standard on all D9R Track-type Tractors.

Below the inlet screen is the air cleaner (2). Inside the air cleaner are two filter elements (primary and secondary). The larger (outside) element is the primary element, and the smaller (inside) element is the secondary element.

An air filter indicator (3) is mounted on the rear of the air cleaner housing. The indicator permits a quick visual check of the air filter elements. As the air filters get dirty and start to restrict air flow, a yellow diaphragm gradually moves toward the red zone at the top of the indicator. When the diaphragm enters the red zone, the air filters must be serviced. To reset the diaphragm, push the button on the bottom of the indicator.

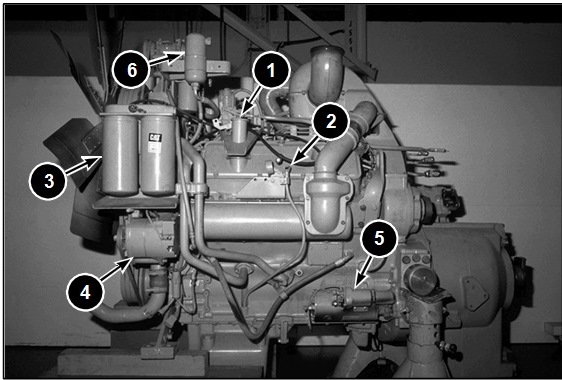

Located on the left side of the engine are the engine oil fill tube (1), the engine oil dipstick (2), two spin-on oil filters (3), a 75 ampere rated belt driven alternator (4), a 24-Volt starting motor (5), and the air conditioner accumulator (6).

On the right side of the engine are the fuel governor (1), belt driven air conditioner compressor (2), turbocharger (3), centrifugal-type water pump (4), engine oil cooler (5), and the piston-type implement hydraulic pump (6).