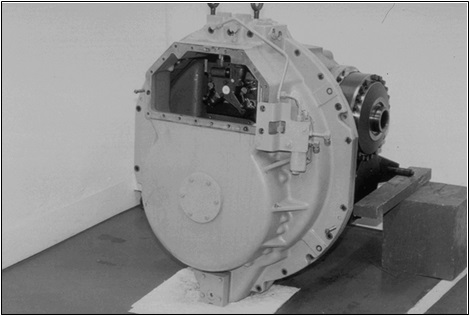

The D9R transmission is located at the rear of the machine for easy removal and installation. The three-speed forward, three-speed reverse planetary power shift transmission transfers power from the engine to the final drives. The transmission contains three hydraulically controlled speed clutches and two hydraulically controlled directional clutches. The operator manually selects the direction and […]

Category: CATERPILLAR

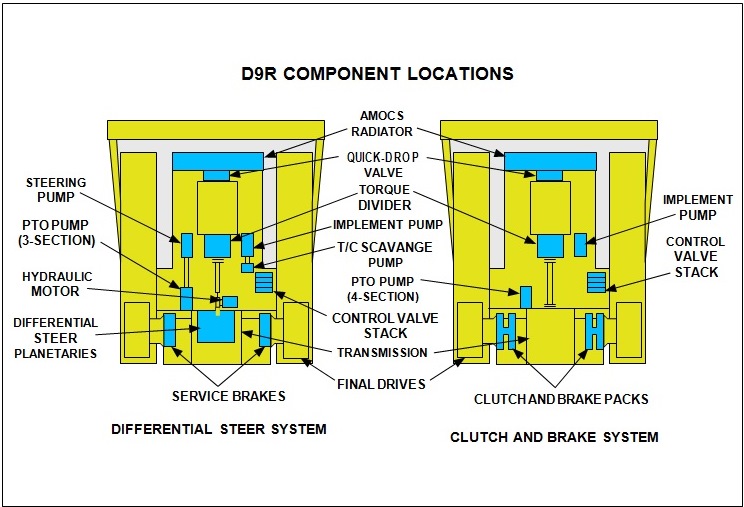

Comparison of Component Locations for Different Caterpillar D9R Version

That illustration shows a comparison of component locations for both the differential steer version and the steering clutch and brake version of the D9R. Component layouts for the two systems are very similar except for the following items: Steering pump on the differential steer machine Four-section PTO pump on the clutch and brake machine compared […]

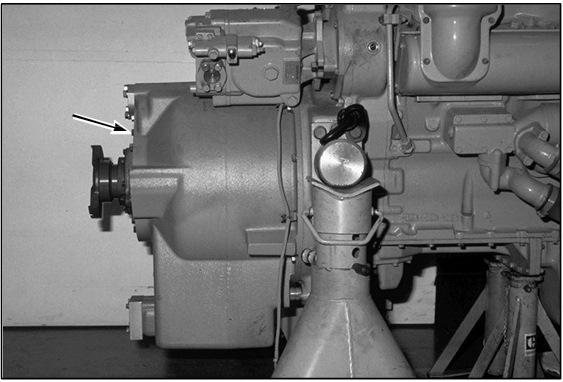

Hydraulic and Mechanical Torque Divider Functions in Torque Converter

The D9R Track-type Tractor uses a torque divider (arrow) to transfer engine power to the transmission. The torque divider in this view is mounted to a 3408 engine. The torque divider is similar to those used on other Caterpillar track-type tractors except the D9R torque divider is also equipped with a freewheel stator. The torque […]

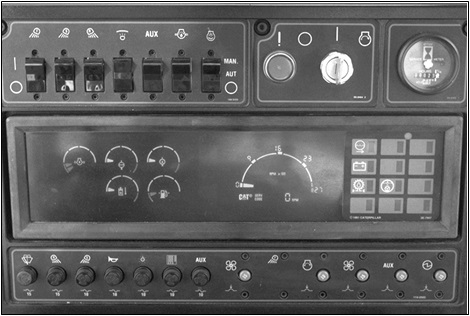

See Monitor Panel Caterpillar D9R

The instrument panel (through Machine Serial No. 7TL1-851 and 8BL1-1052) includes the Computerized Monitoring System (CMS) display used for monitoring the machine systems. The instrument panel also includes the individual system switches, action light, a key start switch, action horn (not visible), service hourmeter, a vacuum fluorescent display panel, and system fuses and circuit breakers. […]

About Fuel Tank Caterpillar D9R

The D9R fuel tank is located on the rear of the machine behind the operator’s station. A strainer in the fuel fill tube keeps debris out of the fuel tank during refueling. A vented cap prevents pressure build-up in the fuel tank and also prevents cooling fuel from creating a vacuum. The fuel tank has […]

Introducing Radiator D9R Caterpillar

The D9R is equipped with an Advanced Modular Core System (AMOCS) radiator. The AMOCS has two major advantages over earlier designs. The first advantage is the improvement of the modular core servicablilty. The AMOCS radiator has been designed to include one divided tank below the modular cores. This design eliminates the tank which was formerly […]

HEUI system components (2)

The engine coolant temperature sensor (1) is located in the front of the right cylinder head. This sensor is used with the ECM to control various functions. The following systems or circuits use the temperature sensor output to the ECM: The Caterpillar Monitoring System Coolant Temperature Gauge over the CAT Data Link The High Coolant […]

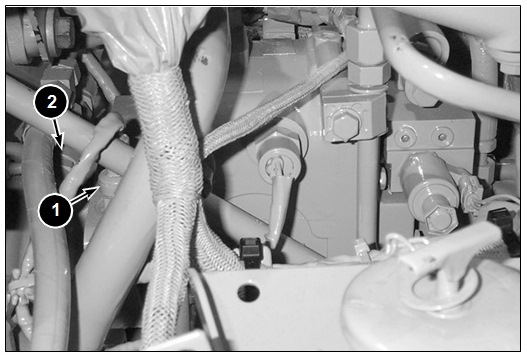

HEUI system components (1)

The atmospheric pressure sensor (1) is installed on the hydraulic supply pump group adapter and is vented to the atmosphere. A foam block below the sensor helps prevent the entry of dirt into the sensor. The sensor performs the following functions: Ambient pressure measurement for automatic altitude compensation and automatic air filter compensation. Absolute pressure […]

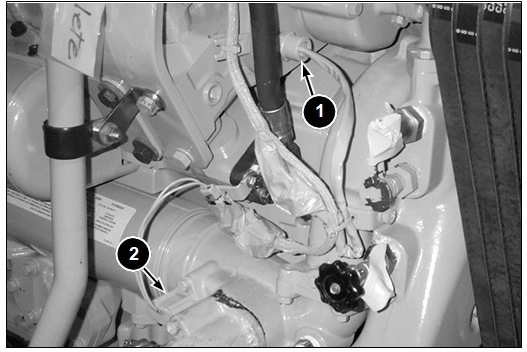

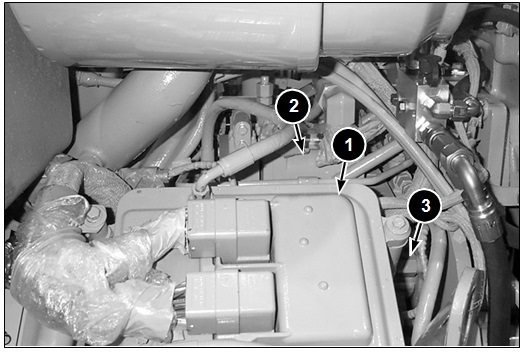

HEUI Hydraulic pump components

The pump control valve (1), also referred to as the “injection actuation pressure control valve,” controls the angle of the pump swashplate which varies the pump oil flow. Also mounted on the hydraulic supply pump group is the hydraulic temperature sensor (2). This sensor is used by the ECM for viscosity compensation to maintain consistent […]

HEUI system components

The principal component in the HEUI system, the Electronic Control Module (ECM, 1), is mounted on top of the right front valve cover. The ECM is the “heart” of the engine. The ECM performs engine governing, timing and fuel limiting. It also reads sensors and transmits data to the instrument display system through the CAT […]