The D9R is equipped with an Advanced Modular Core System (AMOCS) radiator. The AMOCS has two major advantages over earlier designs.

The first advantage is the improvement of the modular core servicablilty. The AMOCS radiator has been designed to include one divided tank below the modular cores. This design eliminates the tank which was formerly attached to the top of the modular cores. By locating both tanks below the modular cores, removal of a singular modular core is simplified. By eliminating the top tank, the seals for all the modules need not be disturbed if only one must be replaced. The maintenance time to replace a single module is considerably reduced. The second advantage of the AMOCS is a higher cooling performance. The modular cores are “two-pass” since both tanks are located below the cores. “Two-pass” means that the fluid from one tank is sent up one tube in the core and sent down the other side of the same core to the adjacent tank. This feature allows the fluid to make two cooling passes through the modular cores, thereby improving cooling performance.

The cooling system on the later D9R (ACL and ABK) has been changed from the earlier D9R. A separate water pump has been added to the engine to provide lower temperature coolant through the aftercooler.

Cooler air is supplied to the engine, which provides improved efficiency and reduced emissions.

This design is referred to as a “Separate Circuit Aftercooler (SCAC)” system. The SCAC pump draws coolant from the left two cores of the AMOCS radiator. The temperature of this coolant is lower than in the other seven cores. The coolant in the two left cores is sent through the cores a second time. The coolant makes four cooling passes instead of two as in the remaining cores. The left cores are separated from the other cores by a baffle plate in the bottom tank. The baffle plate functions as an orifice, which allows some of the cooled jacket water from the engine to flow through the left cores and be recirculated. The SCAC pump then sends this coolant to the aftercooler.

The return coolant from the aftercooler goes through the front of the split bottom tank, then passes up and down the left cores to the left rear section of the split bottom tank. The SCAC pump draws coolant from this reservoir. This coolant then flows through the aftercooler to lower the temperature of the inlet air to the engine for more efficient combustion and reduced emissions.

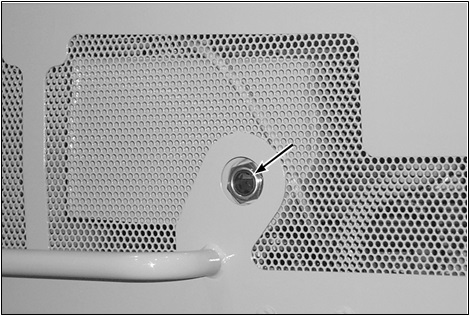

The fill tube is located in the surge tank for the cooling system. The surge tank is located on the right side of the engine compartment. Access to the fill tube is provided by lifting a spring hinged door on top of the engine compartment. Correct coolant level can be checked two ways. A sight glass (arrow) in the surge tank is visible through a hole in the side of the engine compartment. The sight glass should always show fluid. If any air can be seen in the sight glass, coolant needs to be added to the surge tank. A fluid level indicator is located inside the fill tube. The indicator should be submerged by the coolant in the surge tank. If this indicator is visible, fluid must be added to the surge tank. When adding coolant to the system, fill the surge tank to the bottom of the stand pipe in the neck of the fill tube.