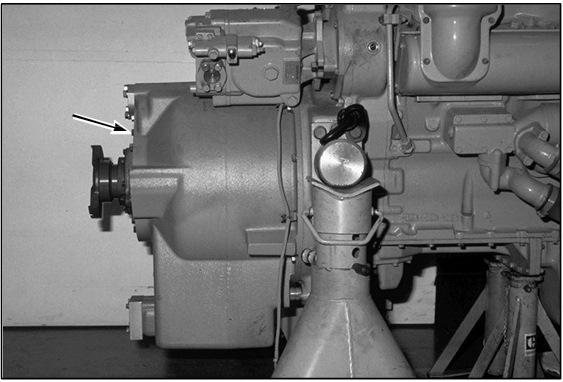

The D9R Track-type Tractor uses a torque divider (arrow) to transfer engine power to the transmission. The torque divider in this view is mounted to a 3408 engine. The torque divider is similar to those used on other Caterpillar track-type tractors except the D9R torque divider is also equipped with a freewheel stator.

The torque divider provides both a hydraulic and a mechanical connection from the engine to the transmission. The torque converter provides the hydraulic connection, while the planetary gear set provides the mechanical connection. During operation, the planetary gear set and the torque converter work together to provide an increase in torque as the load on the machine increases.

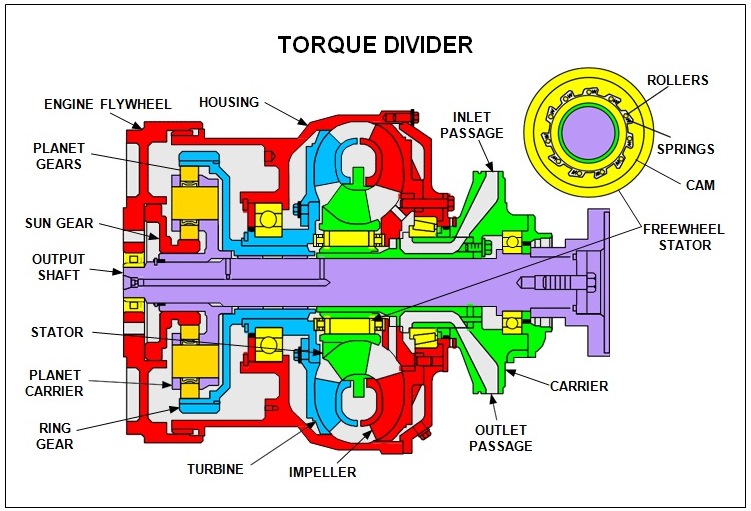

This illustration shows the torque divider that is used in both versions of the D9R. The impeller, rotating housing, and sun gear are shown in red. These components are on a direct mechanical connection to the engine flywheel (also shown in red). The turbine and the ring gear, shown in blue, are connected. The planetary carrier and output shaft, shown in purple, are also connected. The stator and carrier are shown in green.

The planetary gears and shafts are orange. Bearings and the lockup mechanism for the stator are shown in yellow.

Because the sun gear and the impeller are connected to the flywheel, they will always rotate at engine speed. As the impeller rotates, it directs oil against the turbine blades, causing the turbine to rotate. Turbine rotation causes the ring gear to rotate. During NO LOAD conditions, the components of the planetary gear set rotate as a unit at the same rpm. The planet gears do not rotate on their shafts.

As the operator loads the machine, the output shaft slows down. A decrease in output shaft speed causes the rpm of the planetary carrier to decrease. Decreasing the planetary carrier rotation causes the relative motion between the sun gear and the planet carrier to cause the planet gears to rotate. Rotating the planet gears decreases the rpm of the ring gear and the turbine. At this point, the torque converter multiplies torque and the planetary gear set splits the torque.

An extremely heavy load can stall the machine. If the machine stalls, the output shaft and the planetary carrier will not rotate. This condition causes the ring gear and turbine to slowly rotate in the opposite direction of engine rotation. Maximum torque multiplication is achieved just as the ring gear and turbine begin to turn in the opposite direction.

The torque divider is also equipped with a freewheel stator. The stator is splined to a cam which rotates around the stationary carrier in only one direction. Machined into the cam are tapered openings which contain rollers and springs. Spring force holds the rollers against the taper and carrier and restricts the cam from turning.

When the machine is under a load, and the impeller and turbine are rotating at different speeds, the stator is held stationary because the rollers are wedged in the taper of the openings by spring force. This mechanical connection keeps the stator stationary and allows oil flow to be directed back to the impeller and multiply the torque.

During all load conditions, the torque converter provides 75% of the output, and the planetary gear set provides the remaining 25% of the output. The size of the planetary gears establishes the torque split between the hydraulic torque and the mechanical torque.

When the machine speed increases with no load, the speed of the turbine and impeller increases. During this condition the stator does not need to redirect oil back to the impeller. The stator begins to turn in the same direction as the impeller and turbine and moves the rollers from the tapered openings against the spring pressure. The mechanical connection between the cam and the stationary carrier is broken. The stator, turning freely with the turbine and impeller, will reduce turbulence of the oil in the torque converter. The lack of turbulence in the torque converter permits the engine to work easier to reduce fuel consumption and minimizes heat build-up in the power train oil system.