Aftercoolers are used in conjunction with turbochargers in order to lower the temperature of the air coming from the turbocharger before the air enters the cylinders. This causes the air to be more dense, therefore contain more oxygen in a given volume. This increase in oxygen in the cylinders translates into greater power and efficiency from the engine.

There are different types of aftercoolers that are used on Caterpillar engines: All aftercoolers serve the same purpose however, remove heat from inlet air providing cooler and more dense air to the cylinder.

Air to Air Aftercooler (ATAAC)

With the air to air aftercooled system, a separate cooler core is installed in front of the vehicle engine radiator. Ambient temperature air is moved across the aftercooler core by the engine fan.

Pressurized air from the turbocharger is cooled by the air to air aftercooler before entering the intake manifold. This is an extremely effective method for cooling the turbocharged air when a large volume of fresh cool air can be pushed through the aftercooler. For this reason this is the configuration found most often in on-highway truck applications.

Jacket Water Aftercooler (JWAC)

The jacket water aftercooler system has a coolant charged core assembly. It uses the engine coolant in order to cool the air charge entering the cylinders. Coolant from the water pump flows through the aftercooler core. Pressurized air from the turbocharger is cooled by the aftercooler before entering the intake manifold.

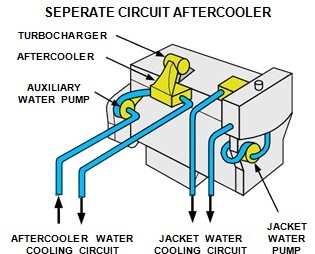

Separate Circuit Aftercooler (SCAC)

A separate circuit aftercooler system is similar to the jacket water aftercooler system with minor differences. A separate cooling circuit from the jacket water of the engine is used to cool the engine. The jacket water acts as normal, cooling the engine head, block, transmission oil, etc. The separate circuit aftercooler system has a dedicated water pump, lines, and heat exchanger for the aftercooler. This system is typically used in applications where maximum aftercooling is required. Many marine applications utilize separate circuit aftercoolers in conjunction with a heat exchanger that is designed to use the keel water for cooling the circuit. Many of Caterpillar’s large mining trucks also use this type of aftercooler.